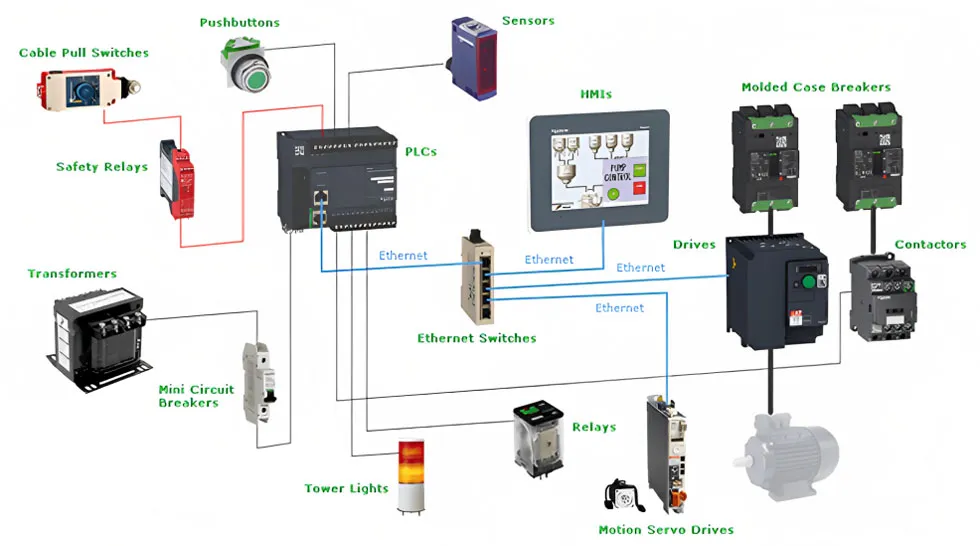

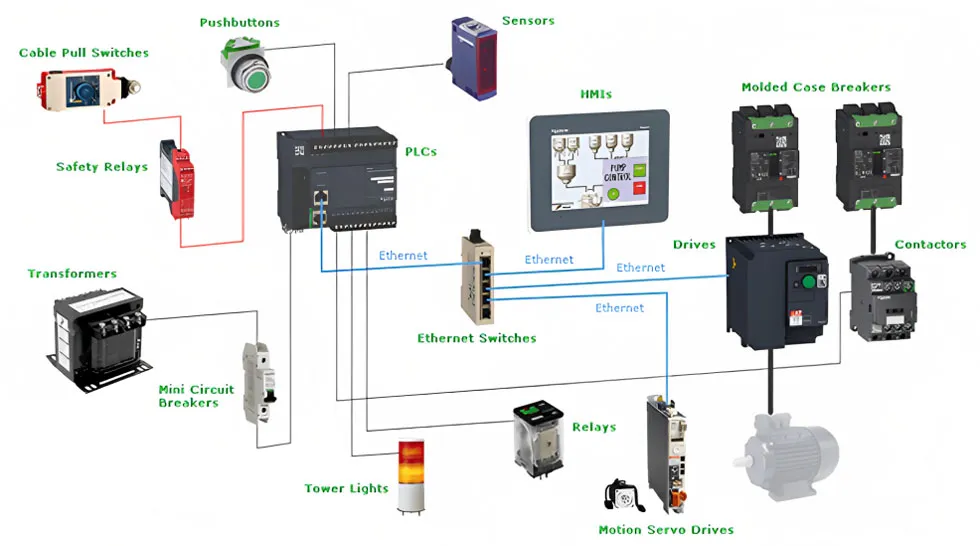

Schneider Electric is an industrial automation and control products company that offers products for data acquisition, monitoring, processing, and stopping machines. It brings the applications into easy, reliable, safe operation and also ensures maximum efficiency and productivity with the implementation of smart solutions. They provide SCADA, HMI, Sensors, Motion Control, PLC, and more.

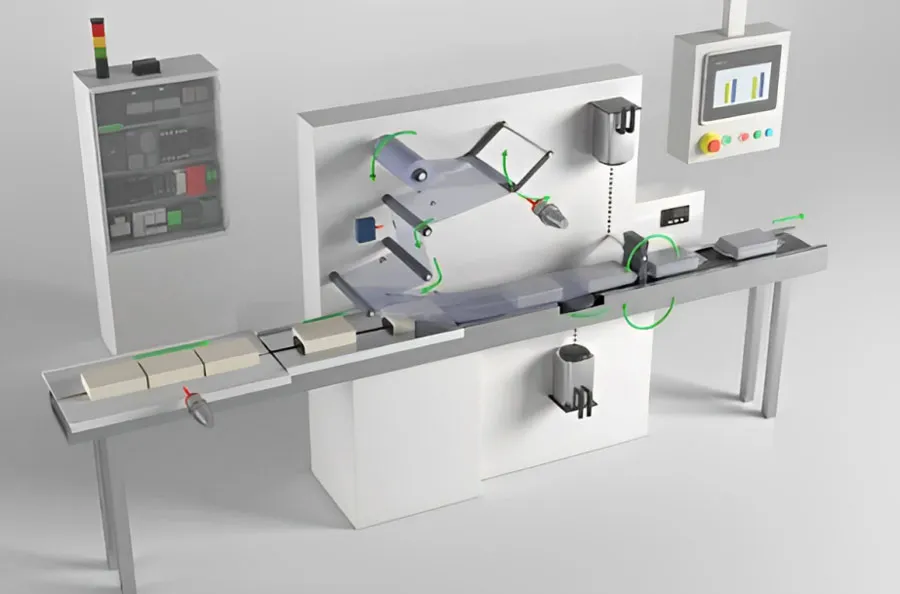

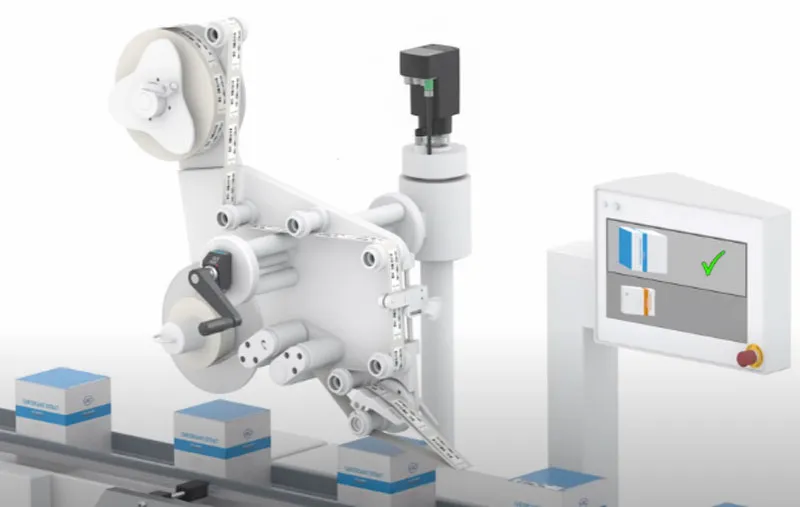

This is a filling and capping machine that included all of the Schneider products to form a solution that increased the efficiency and performance of your machines. It has operation interfaces, machine safety, detection of product passage and filling goods, a machine and motion control system, and the control cabinet.

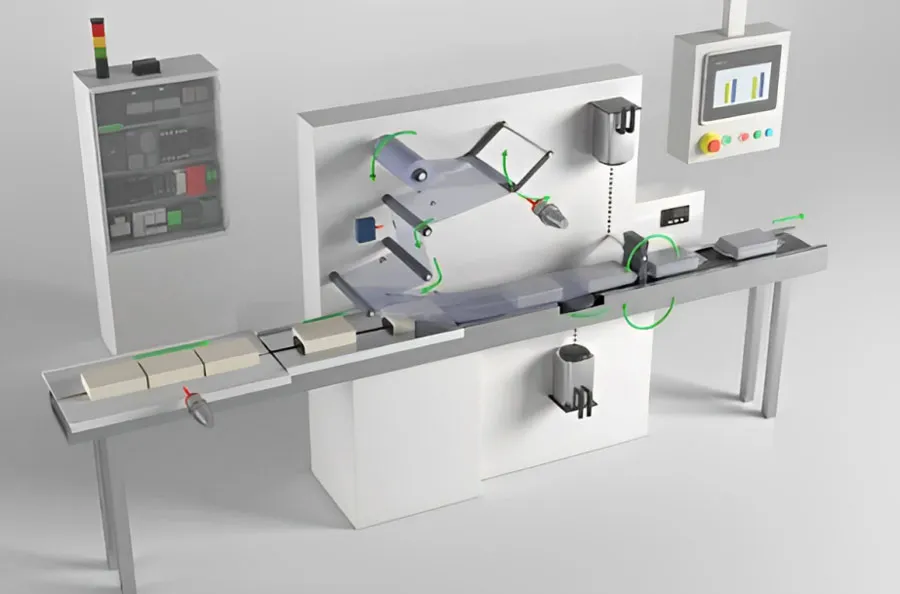

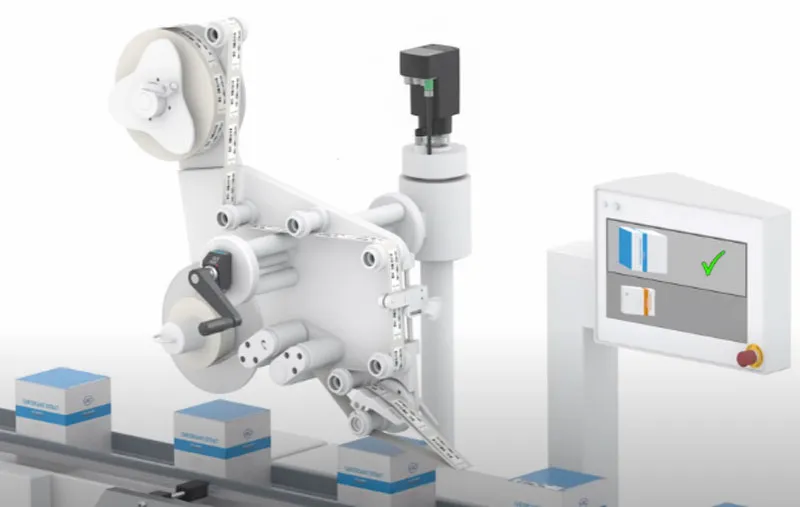

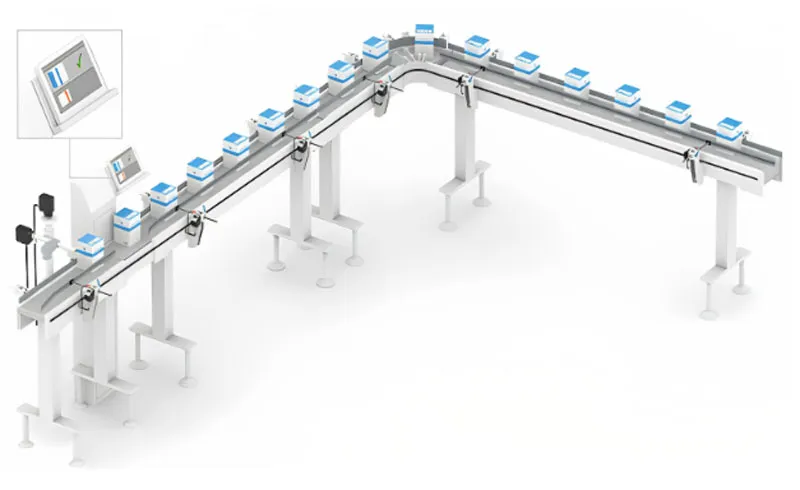

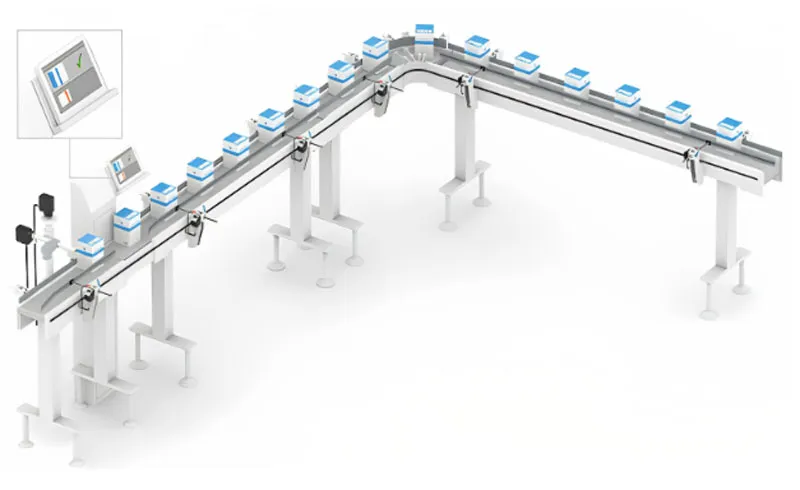

This is a horizontal packing machine that simplifies engineering processes using controllers with fully embedded features, intuitive tools, ready-to-use-architectures, and dedicated software functionality. It included operation interfaces, machine safety, colour marker detection, film presence and tension sensors, detection of product passage, sealing and cutter positioning, temperature control, motion and machine controllers, and the control cabinet.